什么是X射线荧光镀层涂层测厚法?

材料的涂层厚度是一个重要的工艺参数。它直接影响零件或产品的耐腐蚀性、装饰效果、导电性、产品可靠性和使用寿命。因此,涂层的厚度在产品质量、工艺控制和成本控制中起着重要作用。

什么是电镀/涂层?

电镀是指在一些物品的金属表面涂上一层有机物,或薄薄的一层金属或仿制某种贵金属,为了美观或存放,在普通金属表面镀上这种贵金属。 .复合镀层的制备是在镀液中加入一种或几种不溶性固体颗粒,使固体颗粒与金属离子共沉积的过程。它实际上是一种金属基复合材料。

什么是涂层厚度测试?有哪些方法?

涂层厚度测试检测材料表面金属和氧化物涂层的厚度。镀层厚度的测量方法主要有金相法、X射线荧光法和扫描电子显微镜测量法等。

XRF镀层测厚仪俗称X射线荧光测厚仪、镀层测厚仪、薄膜测厚仪、薄膜测厚仪、金镍测厚仪、电镀薄膜测厚仪等,主要用于精确测量涂层的厚度。金属电镀层。

XRF涂层测厚仪:

俗称X射线荧光测厚仪、镀层测厚仪、薄膜测厚仪、薄膜测厚仪、金镍测厚仪、电镀薄膜测厚仪等;

功能:精密测量金属镀层厚度;

应用范围:测量涂层、涂层、薄膜、液体的厚度或成分,测量范围从12(Mg)到92(U)

使用X射线的非接触式厚度测量装置可以让探测器检测穿透目标物体的量子X射线量,或穿透目标物体的荧光X射线量来测量厚度的目标对象。探测器探测到的量子X射线或荧光X射线的数量因目标物体的材料而异,其吸收系数、密度和厚度各不相同。无需比较目标物体的量子 X 射线量和穿过目标物体并从 X 射线目标发射的 X 射线量。厚度。

校准曲线是通过比较具有基层的参考样品的基层和由其上形成的薄膜层形成的基层中特定元素散射的信号强度与薄层厚度之间的差异来确定的。通过将具有基层的参考样品的基层和其上形成有基层的目标样品的基层中的特定元素散射的信号与校准进行比较来确定目标样品膜层厚度。

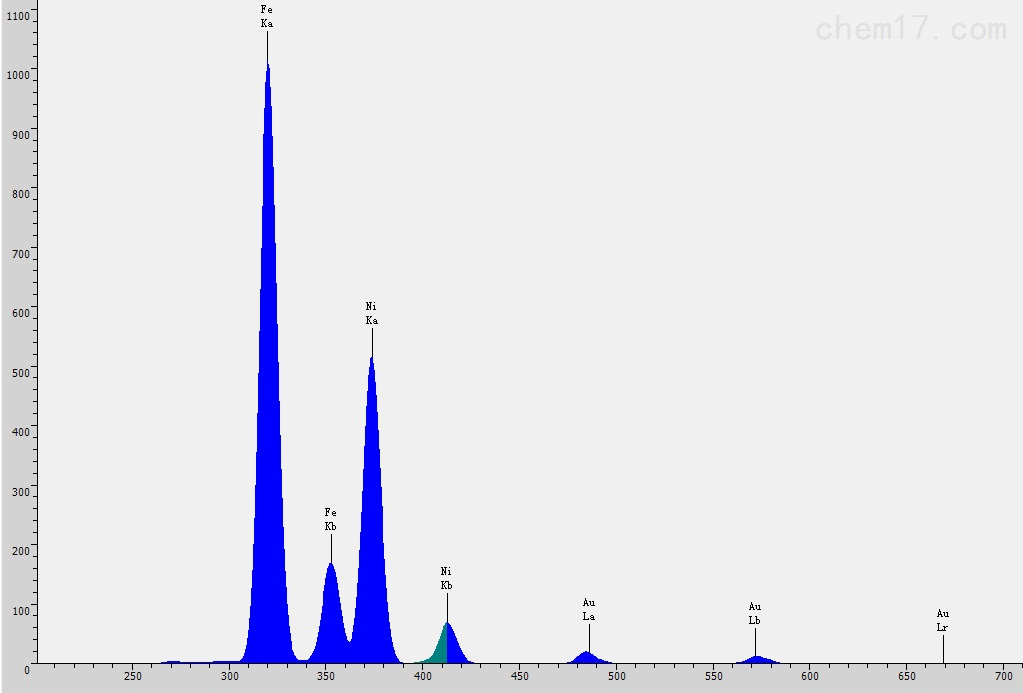

典型的镀层厚度光谱图(铁镀镍镀金)

The coating thickness of the material is an important process parameter. It directly affects the corrosion resistance, decorative effect, electrical conductivity, product reliability and service life of parts or products. Therefore, the thickness of the coating plays an important role in product quality, process control, and cost control.

What is plating/coating?

Plating refers to coating a layer of organic matter, or a thin layer of metal or imitating some kind of precious metal, on the metal surface of some items for good-looking or storage, and plating this precious metal on the surface of ordinary metal. . The preparation of composite coating is a process of adding one or several insoluble solid particles to the plating solution to co-deposit the solid particles and metal ions. It is actually a metal-based composite material.

What is the coating thickness test? What are the methods?

Coating thickness test detects the thickness of metal and oxide coatings on the surface of the material. The measurement methods of coating thickness mainly include metallographic method, X-ray fluorescence method and scanning electron microscope measurement method and so on.

XRF coating thickness gauges are commonly known as X-ray fluorescence thickness gauges, coating thickness gauges, film thickness gauges, film thickness testers, gold-nickel thickness testers, electroplating film thickness gauges, etc. They are mainly used to accurately measure the thickness of metal electroplating layers.

XRF coating thickness gauge:

Commonly known as X-ray fluorescence thickness gauge, coating thickness gauge, film thickness gauge, film thickness tester, gold nickel thickness tester, electroplating film thickness gauge, etc.;

Function: precise measurement of the thickness of the metal plating layer;

Application range: measuring the thickness or composition of coatings, coatings, films, liquids, measuring range from 12 (Mg) to 92 (U)

The non-contact thickness measuring device using X-rays can allow the amount of quantum X-rays penetrating the target object to be detected by the detector, or the amount of fluorescent X-rays penetrating the target object to be detected to measure the thickness of the target object. The amount of quantum X-rays or fluorescent X-rays detected by the detector in response to the material of the target object varies in absorption coefficient, density, and thickness. It is not necessary to compare the amount of quantum X-rays of the target object and the amount of X-rays irradiated to pass through the target object and emitted from the X-ray target. thickness.

The calibration curve is determined by comparing the difference between the intensity of the signal scattered by the specific element in the base layer of the reference sample having the base layer and the base layer formed by the thin film layer formed thereon with the thickness of the thin film layer, and The target is determined by comparing the intensity difference between the signal scattered by a specific element in the base layer of the reference sample having the base layer and the base layer of the target sample having the base layer formed thereon with the calibration curve. The thickness of the film layer of the sample